Human energy needs have continued to rise across the globe year after year, and so has the need for cleaner energy sources. The energy industry encompasses renewable and nonrenewable energy sourcing and the manufacturing of parts that both sectors need. With the growing concern around the harmful effects of carbon emissions, green energy sources are becoming more and more accessible. So much so, that developed countries have fully switched over to clean energy sources as their primary method.

Since rapid industrialization began in the 1780s, energy systems and technologies have become more sophisticated. It became increasingly difficult for manufacturers to meet energy production needs until the development of CNC machining in the 1950s. CNC machining now plays a major role in developing the world’s energy sector, notably in renewable energy development. CNC machining achieves the use of precision parts with the ability to sustain greater loads, reduce labor, save on manufacturing costs, decrease carbon footprint, and achieve economies of scale.

Read on to learn how CNC machining benefits and continues to pioneer change in the energy sector throughout the world.

CNC Machining for Nonrenewable Energy Parts

The oil and gas sector, which dominates the nonrenewable energy sector, requires parts like downhole tools, gap subs, directional drilling parts, and many many more. The oil and gas sector is making extremely swift progress towards a full recovery from the pandemic. Oil prices remain high while work and travel continue to resume across the world, creating a boom for the oil and gas industry. Oil and gas companies are notably focused on financial health and cutting costs to recover from COVID losses. In turn, companies are reevaluating how they make or buy their parts to operate more efficiently. Caprice MachineWorks can help navigate this pivotal time for oil and gas producers by providing quick-turn services with some of the lowest shop rates around. We specialize in oil and gas parts. Contact us today for a quote!

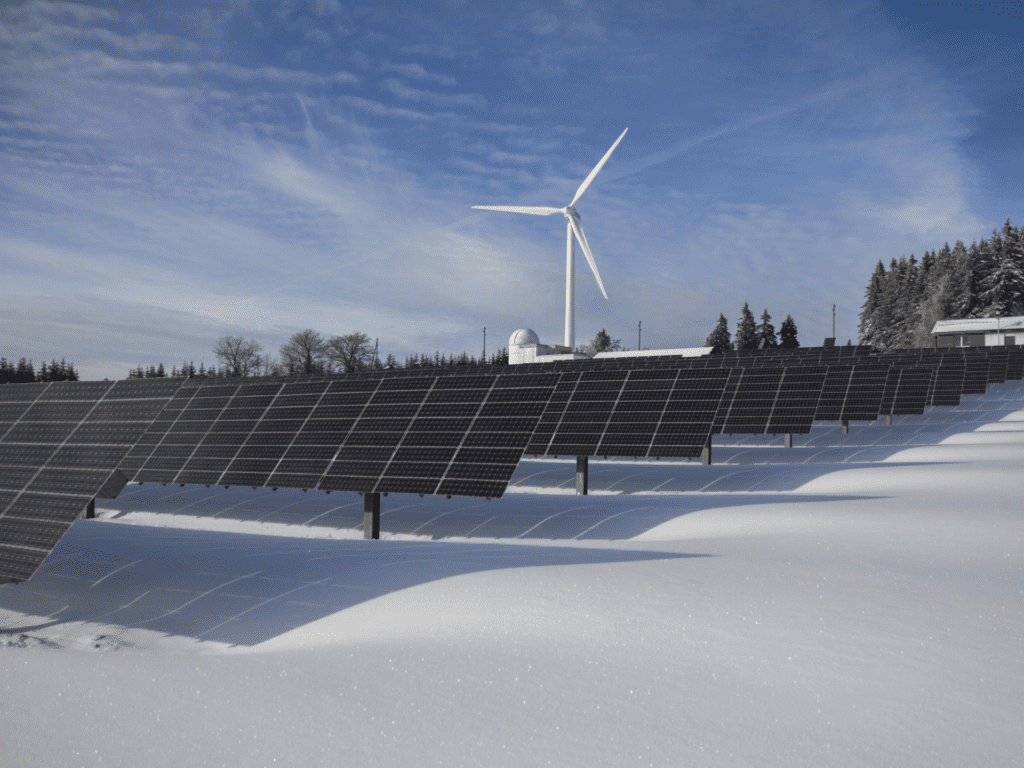

CNC Machining for Renewable Energy Parts

Renewable energy sources continue to grow at a lightning-fast pace. Parts required for the renewable energy sector include parts like turbine blades or brackets for mounting solar panels which are used in the hydropower or solar power sectors. With the near unprecedented growth in nonrenewable and renewable energy and the highly competitive markets of both, many energy-part manufacturers are rethinking their production processes. Most shops are already utilizing CAD/CAM software parallel to powerful and complex CNC machines, but the truly successful shops will be continuously optimizing their machining processes. Caprice Machineworks continues to aggressively optimize our machining processes for energy parts, and we can help you solve your make-or-buy conundrum today!

Why is CNC Machining Used in the Energy Industry?

CNC machining is a cornerstone in the energy industry because each part utilized in the production of energy must be built to withstand extreme circumstances, such as high pressure and heat. This requires highly precise machining processes and a skilled machinist to produce parts with accuracy and durability. The materials of parts used for energy production must be of the highest durability and strength as well.

This leads to a problem as heat-tolerant metals are usually harder to machine. Feeds and Speeds can be reduced by up to 65% by using difficult materials, but certain materials are necessary to use in order to produce parts that withstand conditions. Manufacturers still need an efficient method to remove massive amounts of material and expedite the production process. CNC machining makes it possible to machine these durable metals with exceptional finishes, without error, and in as few operations as possible. CNC machining has been a catalyst for energy part production, and today it is a necessity to produce parts with enough durability and precision to last.

How is CNC Machining Changing the Energy Industry?

CNC machining is highly available and used in energy sectors because of these benefits:

- Parts used in energy production and power generation must be highly precise. Equipment such as solar panels, generators, and turbines are complex and require components made with high manufacturing accuracy.

- CNC machining brings flexibility in manufacturing products in different volumes.

- There is flexibility in manufacturing both small and large parts.

- Products in bulk production are highly consistent and accurate.

- CNC Machining is entirely electronic, which reduces movement and carbon footprint.

- CNC Machines can be modified according to needs and boost production efficiency.

What Kinds of Materials Are Used in Energy Part Production?

The heat-resistant metals that are used the most in the energy sector are specialty alloys and titanium. Stainless steel, precision steel, and aluminum are often used as well and can be reversed for less essential components. Plastics are used at times to machine a variety of other parts.

Research and Prototyping

Renewable energies such as solar, wind, and hydro still have a lot of room for research. Exploring new and complex designs paired with rapid prototyping is vital to further the innovation of energy production. CNC machining constitutes a major building block for such processes. At Caprice MachineWorks, we specialize in prototyping and bring 50+ years of combined experience in prototyping and design. If you have a design or concept, we can help you bring it to life!

Caprice MachineWorks CNC Machining Capabilities for the Energy Industry

The success of component production in the energy manufacturing industry depends on the quality, speed, and accuracy of production. Caprice MachineWorks provides unmatched CAD/CAM solutions to meet the aggressive demands of energy production today. These solutions include:

- State-of-the-art CAM tools for resolving complex machining issues

- Streamlined 3 and 4-axis cutting, trimming, and drilling

- Advanced toolpaths that effectively target uncut areas

- Toolroom and production style CNC lathes

Our multi-axis CNC setup is excellent for Rapid Prototyping, and we work with tons of materials. Our expert engineers can help you with your most complex project and deliver exceptional results.

Ready to Get in Touch?

If you need to source parts for the energy industry, need difficult materials machined, or need to boost efficiency, reach out now! We are ready to help you with your next project!